Fiberglass vs. Aluminum: What’s Better for Fiber Optic Splicing Trailers?

August 7, 2019

You are likely considering several factors as you select a fiber optic splicing trailer. Does the workspace fit your needs? Does the trailer provide the comfort and safety necessary to get the job done efficiently? Do you have enough space to work? And often the factor that can really impact your purchasing decision…does this fit within my budget?

All of these factors and more are important considerations when choosing a fiber splicing trailer, but one of the most important things to consider when evaluating your options – and budget – is how well will this trailer serve my business in the long-term. One important detail makes all the difference when investing in a fiber optic splicing trailer—what is the body made of?

At Pelsue, all of our fiber splicing vehicles come standard with an aluminum frame, custom craftsmanship and most significantly, a fiberglass gel coat body. If you’re looking for reliability, durability and a lifetime of value, fiberglass is your best bet. Here are a few reasons why:

Fiberglass is Built-to-Last

Fiberglass is more durable – and easier to repair – than aluminum. Easily-dented aluminum often means frequent and costly repairs. Fiberglass, on the other hand, can be repaired more readily by laying down additional fiberglass mesh. Finding a place to make repairs in a timely manner is much easier for fiberglass trailers. In addition to traditional auto body shops, most boat repair shops are also able to repair fiberglass trailers. A repaired fiberglass body also holds its resale value much better than a dented aluminum trailer, making a fiberglass trailer a stronger long-term investment, even if your business eventually outgrows it.

Fiberglass Repair Case Study:

An accident involving your fiber optic trailer doesn’t have to be disruptive to your operations or budget. Once everyone involved in the incident is taken care of, it’ll be time to take care of repairs to the body. Luckily, if you invested in a fiberglass body, these repairs can be made easily to render your trailer good as new.

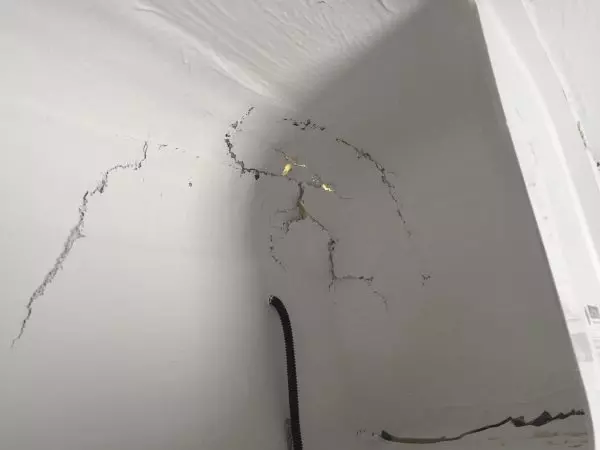

Recently, a Pelsue client saw their trailer land on its side as a result of an accident. The fiberglass shell was back in action quickly as a result of fiberglass’ durability and ease of repair. You’ll see in the before and after photos below just how effective the repair (achieved by adding more mesh and gel) was. And note, this would have been a much more costly, time consuming and labor-intensive repair on an aluminum trailer.

Rear Curb (Interior) Before and After:

Rear Curb (Exterior) Before and After:

Front Curb (Interior) Before and After:

Fiberglass is Easier to Maintain than Aluminum

Fiberglass stays drier and is easier to clean than aluminum bodies. Aluminum attracts and holds on to dirt and moisture, making it very difficult to keep clean and dry, both inside and out. A clean, dry work environment is imperative to the sensitive work done by technicians in fiber splicing trailers, and the tendency for aluminum to sweat will not do you or your team any favors.

Fiberglass Provides Long-Term Efficiency

Fiberglass bodies are generally lighter than aluminum bodies, and a lighter trailer means better gas mileage, and ultimately, reduced fuel costs. Fiberglass also insulates better than aluminum, so it will hold heat or keep the space cool during extreme weather.

It’s true that aluminum trailers are often cheaper than fiberglass trailers, yet the dollars you may save at the onset will certainly be spent down the road on higher maintenance costs and fewer years between trailer replacement. You can also sell your fiberglass trailer for a much higher resale value than any aluminum bodied trailer.

In addition to the top-of-the-line quality with fiberglass bodies, Pelsue FiberLite® trailers are designed from the ground up for the sole purpose of creating the best space for fiber splicing in the field. Pelsue FiberLite® fiber optic trailers are durable, easier to maintain and provide a long-term investment that will positively impact your bottom line for years to come. Contact us today to begin building your fully customizable fiber optic splicing trailer!