Material Matters: The Advantage of Pelsue Work Tent Fabric

May 25, 2020

Manufacturing a high-quality product starts with premium materials.

Pelsue has been producing top-level equipment for over half a century, we’ve been able to form relationships that enable us to source the best materials for each application.

Care and attention to detail at every stage of production—from design to supply to manufacture—is crucial to ensure our equipment works for you. So, from time to time, we like to take a look at some of the materials we use in greater detail.

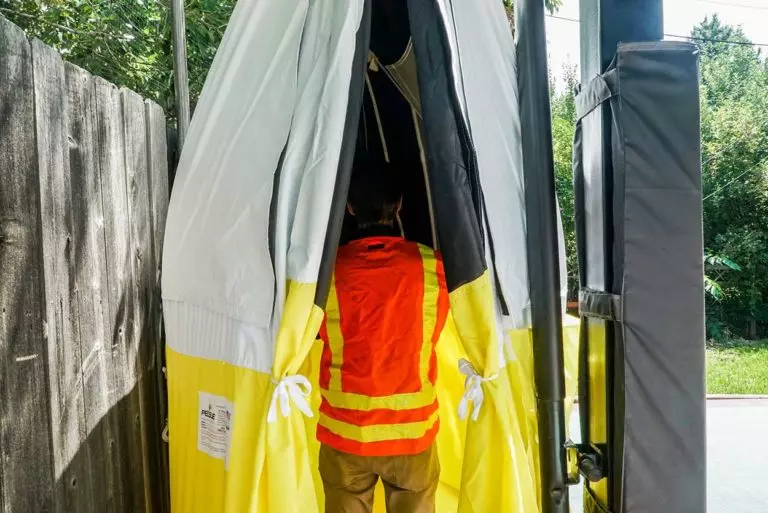

Crews everywhere rely on their Pelsue work tents to protect them from the elements wherever they go. Whether splicing fiber, working in trenches, welding, or performing numerous other outdoor jobs, our work tents help keep you covered.

Given that, we think it’d be appropriate to look at the fabric that makes our work tents work for you.

If you explore the specifications on the tent product pages, you’ll notice the fabric used in most of our tents—the Standard, Interlocking, Dual Entry, Trench Series work tents and parts of our Fiber Splicing and All-Weather Series tents—is listed as 250 denier polyester.

Denier is a standard measurement of the density of fabric. Denier is calculated by measuring the weight (in grams) of a single yarn per 9000 meters. Nine thousand meters of silk weighs one gram, so it clocks in at 1 denier (1d). Ballistic nylon, used in the flak jackets of World War II pilots, has a denier of 1,050.

Of course, both of these extremes aren’t exactly suitable for a work tent. A silk work tent would be incredibly expensive, wouldn’t stand up to adverse weather conditions, and would be damaged by the sun’s UV rays. Though we suppose it might look impressive (before it falls apart).

A high-denier fabric, like ballistic nylon, would also make the tent prohibitively expensive. The extra-dense fabric would also mean the tent would be heavy to the point where portability becomes difficult. Plus, you just don’t need ballistic-grade fabric on your tent. At least, we hope you don’t.

250 denier polyester offers a great balance for a work tent. Heavy enough to stand up to rough weather situations, but light enough that transport is easy.

Those who are familiar with camping tents might be asking, “why not use nylon?” Indeed, nylon is the fabric of choice for the higher-end tents manufactured by the outdoor industry. Again, this comes down to need. Camping tents are generally set up on rougher terrain and are pitched for days at a time. These are not things work tents need to deal with. Camping tents also need to be able to fold down to a fraction of their true size, so the fabric is far thinner which means it is prone to tearing.

This, combined with the fact that nylon is more expensive, mean polyester is the cost-effective choice that still gets the job done. Additionally, nylon stretches whereas polyester doesn’t so your tent fabric won’t distort over time. Polyester is also more resistant to UV damage than nylon so being exposed to the sun won’t affect the fabric.

But fabric alone doesn’t make a tent. Untreated and uncoated, any fabric will start taking on water and deteriorate quickly.

Pelsue tents feature a polyurethane coating, which is the most widely used tent coating. Polyurethane offers a high degree of waterproofing.

Waterproofing is often measured using what is called a Hydrostatic Head (HH) rating. This test determines how much water pressure a coated fabric can withstand before water begins to pass through. An HH rating of 1,000 millimeters or more is required before a fabric can be called “waterproof.” Urethane-coated polyester can reach an HH of 10,000 millimeters.

While waterproofing means your Pelsue tent can stand up in even the worst weather conditions, it is important to dry your tent as much as possible before long-term storage and to store your tent in a dry area. Long-term exposure to standing water speeds a process called hydrolysis, whereby water intrudes into the coating and eventually causes it to deteriorate. It’s the same reason you don’t want to leave standing water in a non-stick frying pan. Taking these simple steps will help ensure your Pelsue tent will serve you as long as possible.

That’s one of our main goals here at Pelsue, when it comes down to it. We want our equipment to be with you and your crews for a long time. The longer you work with a piece of equipment, the more you know you can trust it to perform.

When it comes to safety, trust is paramount. More than profit margins or selling you the latest style—we want to make products you trust. For us, that process starts with selecting the best material for the job.