How Strong is Fiberglass? The Material Revolutionizing your Work Equipment.

December 21, 2020

At Pelsue, we depend on fiberglass to make the bodies of our trusted fiber optic splicing trailers. We understand that, if you’re not used to fiberglass vehicle bodies, you might have one very reasonable question: how strong is fiberglass?

The answer is that, pound–for–pound, fiberglass is stronger than steel or aluminum.

While strength isn’t the only consideration in selecting a vehicle body, it is a major one. It is, after all, a matter of both safety and durability. Your crew needs protection, and you want to get every drop of value from your trailer investment.

We’ve discussed some of the other advantages of fiberglass before. Now let’s take a closer look at the question of strength.

What is specific strength?

When evaluating a material, it’s not enough to just look at raw strength. It’s more useful to evaluate based on a material’s specific strength—another term for its strength-to-weight ratio.

If you only look at the breaking point of a given material (the PSI at which that material yields), steel looks stronger. It also weighs more than twice as much what an equal area of fiberglass weighs.

If you made a trailer body entirely out of diamonds, it would be stronger than fiberglass or steel, but there are definitely better uses for your money (by the way, one of our trailers made entirely out of diamonds would weigh 6,803,886 carats and would be a trailer fit for only royalty).

As we discussed in a previous post about carbon fiber, specific strength is measured in the rather inelegant kilonewton meters per kilogram (there’s no SI approved single standard unit for this at this point).

While the exact number for the specific strength of fiberglass varies depending on the specific composite, a good average is about 1,307 kN m/kg. For comparison, stainless steel’s specific strength is 63.1, and titanium is 260.

That’s a massive difference in favor of fiberglass.

As we said earlier, strength is only one factor to consider when selecting material for a trailer. What are some the other qualities that set fiberglass apart?

Cost Efficiency

We know we can’t bring up the idea of a diamond fiber splicing trailer without at least giving a ball park estimate of what that would cost. Let’s just say the median estimate is more than the GDP of Luxembourg.

But even a less ostentatious choice presents cost issues for businesses who need to keep an eye on their budget.

Aluminum, which would be the most obvious choice to replace fiberglass in the body, can cost anywhere from $1.50 to $8.00 more per pound than fiberglass.

And that is only taking into consideration initial manufacturing costs. Should your trailer ever need repair (more on that below), these price concerns come into play yet again.

One of the reasons fiberglass is, overall, less expensive is intrinsic to its manufacturing process. Fiberglass can be poured into a prepared mold to ensure each piece of a trailer is identical and shaped exactly as needed for the trailer.

With aluminum, sheets would need to be fitted to each individual trailer manufactured, increasing the time and cost to produce every individual trailer.

If you can cut costs, save time, and ensure standardization, all while producing a final product that is pound-for-pound incredibly strong, it becomes a simple choice.

And once you have your trailer, our choice to use fiberglass continues to give you an advantage.

Easy to Repair

Of course, you hope to never be involved in an accident. But they do happen, and once you make sure that every person involved is okay, you can rest assured that repairs to the fiberglass are fairly easy to make.

Repairing fiberglass is much more straightforward than repairing aluminum. Often, it’s just a matter of applying more fiberglass mesh to a damaged area.

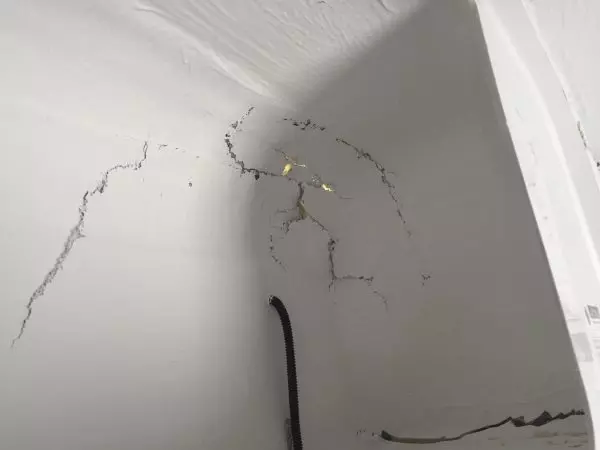

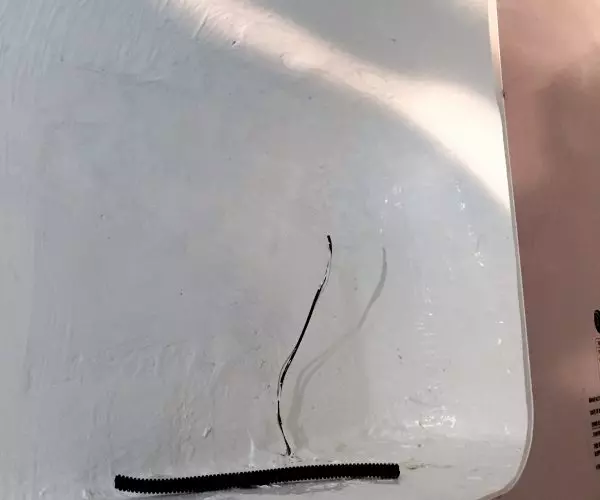

We have a few before and after photos that feature what a simple process it is to patch any cracked or fractured fiberglass areas.

Here we see a before and after of the exterior rear curb repair.

We can also take a closer look of the interior of the rear curb repair.

Notice how the simple repair of adding more mesh and gel allows the trailer to gain its strength back. Compared to the extended process of and aluminum body repair: disassembly, structural repairs, body repairs, priming and painting, reassembly, and detailing; the ease of fiberglass repair allows trailers to be up and running in no time, and ultimately causing you less stress.

For a more in-depth look at fiberglass repair, visit our previous blog post.

In addition to regular auto body garages, boat repair shops should also be equipped to repair your fiberglass trailer. If you can find one willing to work on your trailer, that can reduce the turnaround time greatly.

When making a large purchase like a vehicle, longevity is key to maximizing your value. By combining strength and fixability, the fiberglass body on our fiber splicing trailers puts you in a position to get the most out of your purchase.